Services

In order to be able to implement your yarn finishing requirements, we master a wide range of different technologies. And we are constantly working to expand our know-how so that we can always offer you the most innovative and economical solutions for your products.

Development

In our laboratory, we have all the necessary technologies and capacities to provide you with the best possible support in the development process of your products. Our goal is always to develop the optimal twisted yarns according to the technical requirements of your products but also the economic efficiency of the series production process. In doing so, we draw on the many years of experience of our application engineers and master craftsmen so that you can maintain the speed in your development process.

New materials & material combinations

Special kinds of windings

New coatings

Other manufacturing processes

Camera-based evaluation of the base yarn quality

Yarn purchase

We process a wide range of different materials – both filaments and staple fibers. These include aramid, carbon fiber, polyethylene, HPPE, polyamide, polyester, polypropylene, stainless steel, basalt, glass and also otherwise almost all yarns for technical applications. The fineness ranges from 110 dtex to 120,000 dtex. At the same time, we are continuously searching for new innovative and more cost-effective materials for you.

We will gladly take over the purchase of the basic yarn for you. Due to our large storage areas, we are able to keep sufficient quantities of all relevant yarn types in stock at all times. Thus we can guarantee shortest delivery times. Alternatively, we are also happy to store your yarn templates, tubes and packages with us and supply you with the finished yarn “just in time”.

Assembling and intermingling

As a preparatory process step before twisting or as a stand-alone process, we assemble your base yarn. In addition, we offer you the possibility of intermingling and binding, which can result in both classic and hybrid yarns.

Twisting

Twisting filaments and staple fibers is one of our essential core competences. Our product range extends from simple twists to complex cord constructions. Twisting of compound yarns in particular has become increasingly important in recent years. For the efficient implementation of your requirements, we make use of various twisting technologies and machine sizes, so that we can offer economical solutions for any material and any quantity.

Heat treatment

Due to our diverse possibilities in the field of twisting and winding, we can already adjust the properties of the basic yarn to a large extent. For further refinement of the yarn, in particular to change the elongation and curl tendency, we offer various thermal treatment options. In addition, we can apply various chemical coatings to the yarns, which also specifically influence the yarn properties.

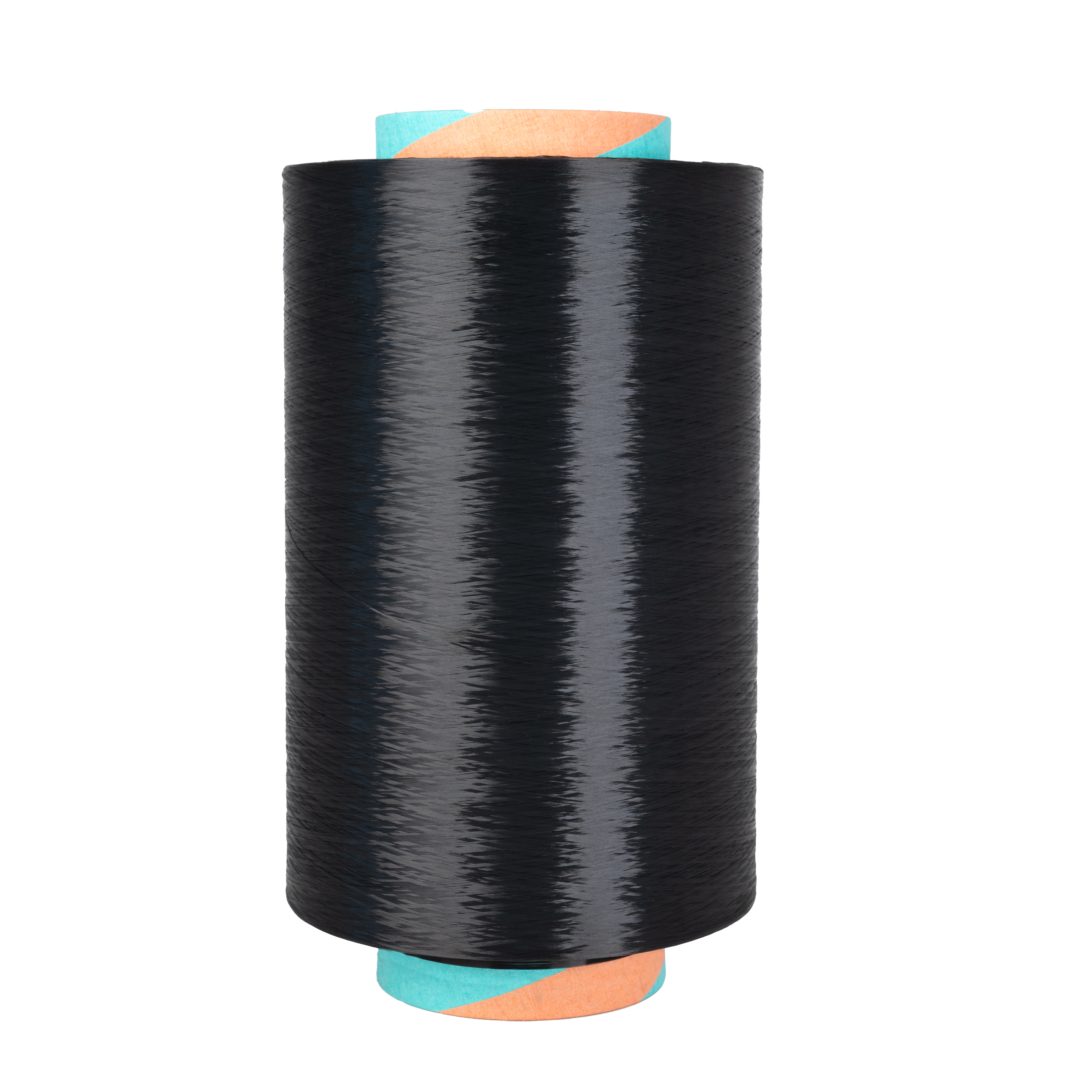

Winding

For us, winding is an essential part of our process chain. Either following the twisting process or as pure rewinding to change the make-up of the basic yarn packages. It is also possible to apply various additional coatings.

We offer you the most diverse presentations in terms of color, material, shape and dimensions of the sleeves. Just as required for your production processes. In addition, of course, the make-up of the bobbins in terms of structure, hardness, yarn reserve, crossover, etc. can be adjusted to a wide extent according to your requirements.